Blog

Custom Tool Spotlight – #10 (0.1935”) 8-Facet Brazed PCD Drill

Welcome to our Custom Tool Spotlight, a series that takes GWS cutting tools and gives them mini biographies. Today, we’re talking about a custom 2-flute 8-facet PCD drill for the aerospace industry.

What’s It For?

This tool is specifically made for drilling Carbon Fiber Reinforced Plastics (CFRP) in a multitude of configurations including unidirectional or multi-directional weaves, CFRP+Al and CFRP+Cu.

What’s Cool About It?

PCD provides the ultimate in wear resistance for machining extremely abrasive non-ferrous materials like CFRP. Unlike diamond-coated tools, which often have some edge rounding due to the thickness of the CVD coating, PCD is able to maintain a sharper edge for improved shearing and less delamination of composite layers.

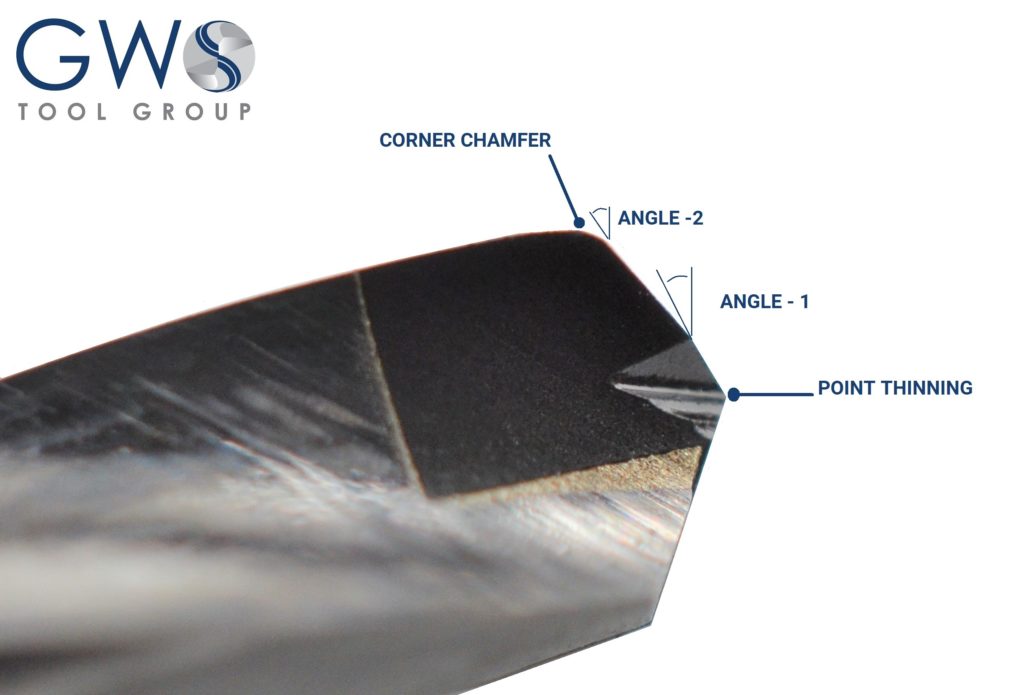

This particular design incorporates two cutting angles that provide multiple shearing angles to ensure fibers in any direction are cleanly cut. Additional thinning prevents walking and corner chamfer extends life while also helping to ensure clean exit holes.

Lastly, proprietary processing technology enables GWS to produce PCD drills and other tools in much smaller diameters than is typical of the industry.

Why Custom?

The layup of the material, thickness and added material stacks are all variables that can demand various geometries and design strategies to address. In addition, some customer needs with respect to quality of finish on exit and entrance holes, internal diameter tolerances, uncut fibers and delamination all play a significant part in what the finished drill design might need to be.

For more information on PCD Drills and how GWS Tool Group can help you, please email our sales team or call 877-GWS-TOOL (877-497-8665) today!