Blog

Autosports Accelerates with the New Alumigator™ ASR5

When Tony from Autosports Engineering (autosportsengineering.com) in Longwood Florida had some aluminum alloy he needed to work on for an automotive part, he quickly noticed the competitor’s end mill he was using was just not meeting his expectations. He was pushing the tool hard and it just couldn’t live up to the standards he required to manufacture the parts he needed.

Tony needed a milling cutter that cut faster and lasted longer. He reached out to Tomas Roman, the Executive Director of Inside Sales at GWS Tool Group who instantly knew we could help. Tomas had our inside sales team immediately send him the all new Alumigator™ Super Rougher (ASR-5). This new beast in the Alumigator™ family of products is a 5-flute, coolant-fed carbide end mill designed specifically for ultra high speed roughing of aluminum alloys.

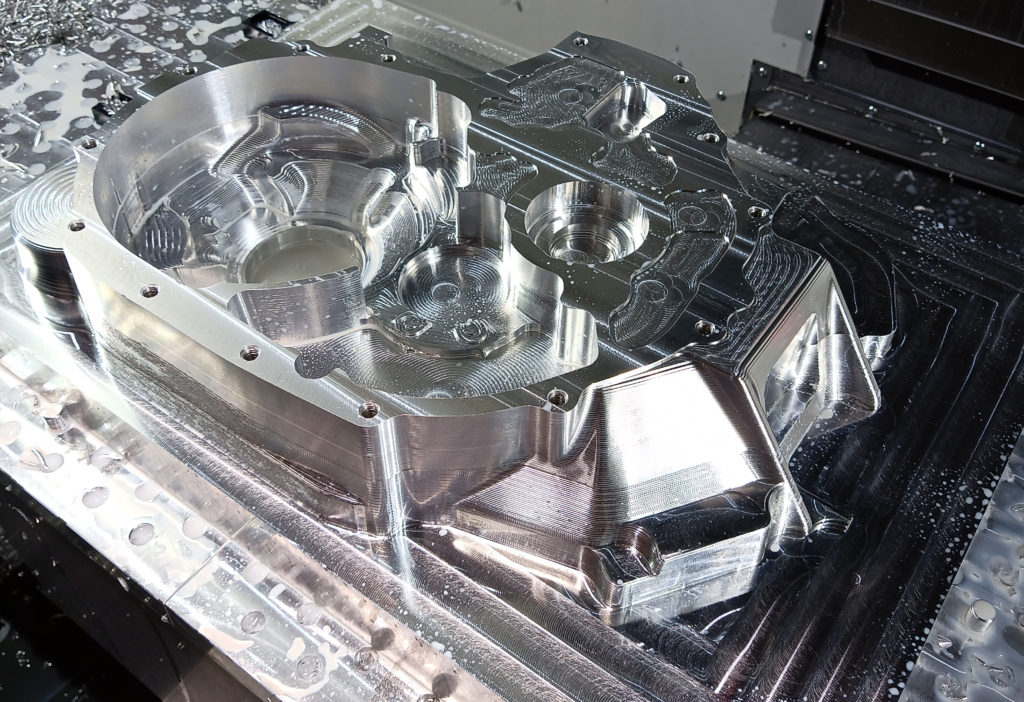

While the new ASR-5 could not ramp as aggressively as its 3-flute brother, it had some other attributes that made up for it. When Tony adjusted his ramp angle to 10 degrees on his HAAS he found he could increase his metal removal rates during pocketing via an extended axial depth of cut. At 12,000 RPM, a 15% step over and 300psi through spindle coolant, he was able to achieve a feed rate of 520 IPM! Tony was floored with the new results he was seeing. “This Alumigator™ cuts amazing, I mean it is really impressive!”, Tony said. He was normally going through 2-3 aluminum end mills a month and when we spoke with him last, he said the Alumigator™ ASR-5 he had tested was still running!

We love when our tools speak for themselves along with saving time and money. Another field test in the win column for GWS Tool Group and the Alumigator™! Want to try the all new Alumigator™ Super Rougher (ASR), click here to request a free test tool today! Available in both coolant-through and solid carbide configurations. To view the new brochure click here. For a glimpse of the ASR-5 in action, check out our video here. For more information, please email our sales team or call 877-GWS-TOOL (877-497-8665) today!