Case Study

6-Figure Cost Savings

Customer

A large Japanese automotive parts manufacturer producing high volume parts via a CNC transfer line.

Part and Material

Automotive Piston – High Silicon Aluminum

The Situation

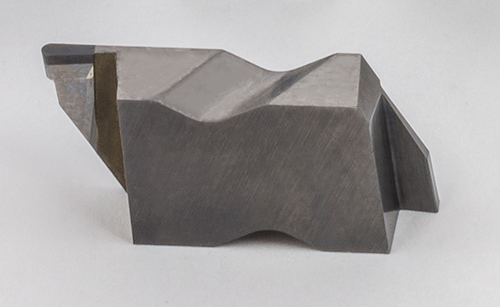

Customer was producing over 100,000 pistons per year, and part of the process was producing the groove around the circumference of the part. For this application, the manufacturer was using a custom PCD grooving insert, made in Japan, to do the job.

The insert was walking slightly, which led to semi-constant adjustments needing to be made all throughout production. Local service and support were also unavailable for reconditioning and troubleshooting. As a result, the distributor on-site reached out to GWS to examine both the new tool and subsequent regrind service.

Current Process Results

- Tool – PCD Custom Grooving Insert

- Cost per Insert: $504.00

- Annual Consumption Cost: $302,400 (600 inserts/year across 3 different inserts)

New GWS Solution

- Tool: Custom PCD-tipped top notch insert

- Cost per Insert: $251.00

- Annual Consumption Cost: $143,640 (570 inserts/year across 3 different inserts)

- Total Cost Savings: $143,070!

Conclusion

GWS designed a more rigid PCD insert that resulted in an up-front hard cost savings of over 50%! The enhanced design eliminated the walking issue, and thereby eliminated the in-process calibration the customer was previously doing. Additional soft cost-savings included lower inventory holding costs via reduced lead times, and a reduced cost-per-part through a comprehensive PCD reconditioning program for all of their PCD insert tools. This is a great example of how when custom solutions are deployed locally, especially specific to the individual customer’s needs, a huge difference can be made.

Interested in finding out more information about our standard and custom tools? Consider contacting the experts who make Custom Come Standard, and let us find the perfect cutting tool for you. Just send us an email at sales@gwstoolgroup.com to get started!

Find Your

Perfect Tool

///////////////////////////////////////

Tool Filter

Search from over 30,000 standard products for a tool that meets your needs.