Blog

Tapping Tip – Finding the Perfect Tap

Warning, the blog your about to read has more information than many of you may want and can be confusing, but it’s what we do in designing a tap.

The actual pitch diameter of a ground thread tap is designated in many ways. It’s dependent on, if it is inch or metric, the amount that it is different than the basic pitch diameter, and the direction of that difference (larger or smaller).

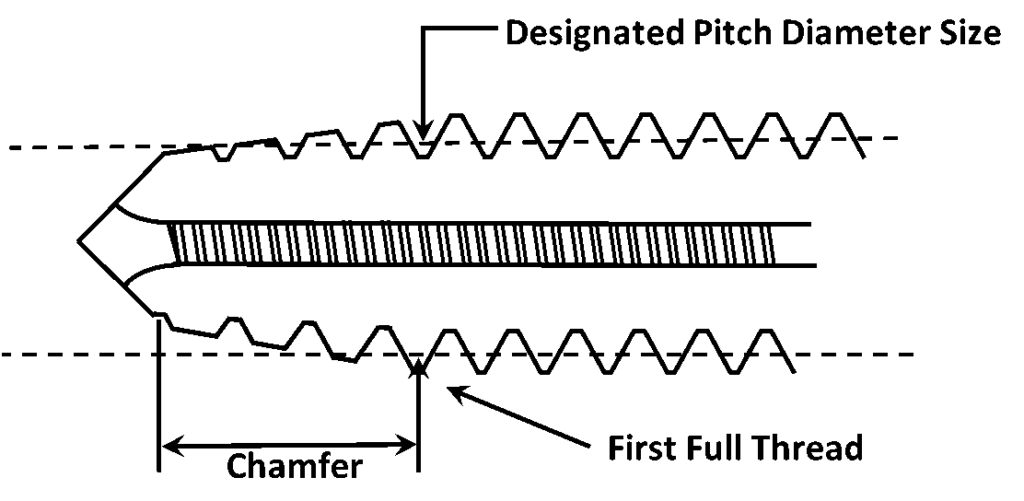

Ground thread taps are designed with “Back Taper”, a decrease in its thread form, including the pitch diameter. The back taper starts at the front of the tap and decreases towards the back. The designated Pitch Diameter size of the tap is located at the first full thread after the chamfer. It’s this thread, that is the last tooth to cut, bringing the thread form including the pitch diameter of the threaded hole to size.

Basic Pitch Diameter

Before we can discuss the tap pitch diameter limit, we need to understand what the basic or nominal pitch diameter of the thread designation is.

The pitch diameter of a basic thread is located where the width of the tooth and the width of the space between them is equal. It is calculated by subtracting the basic height for the given size of thread, from the basic OD of the thread. The value for the height of thread is dependent on the pitch (P) of the thread. On a 60 Degree thread, the formula for the basic height of thread is 0.64952P.

Example, the basic pitch diameter

1/4-20 UNC

OD = 0.2500

P = 1”/20TPI = 0.0500

Basic Height of Thread = 0.64952 x .0500 = 0.032476

Basic Pitch Diameter = 0.2500 – 0.032476 = 0.2175

M6X1

OD = 6.000mm

P = 1.00mm (the 1 in the size designation is the pitch not a TPI)

Basic Height of Thread = 0.64952 x 1.00mm = 0.64952mm

Basic Pitch Diameter = 6.000mm – 0.64952 = 5.350mm

H or L Limits (inch taps)

H and L limits are used for inch size ground thread taps. H (high) represents a pitch diameter that is larger than the basic pitch diameter, and L (low) represents a pitch diameter that is smaller. The number after the H or L, indicates the amount it is different than the basic pitch diameter. Each number after the H or L is equal to 0.0005, so an H3 or L3 is equal to 0.0005 x 3 or 0.0015. The H (high) limit is the maximum pitch diameter of the tap, whereas an L (low) limit is the minimum pitch diameter of the tap. The minimum value for the H limit, and the maximum limit of an L limit, are derived by applying the tolerances from the tap standards. I should mention that H and L limits are also expressed as GH or GL, with the G being that tap has a ground thread, either designation, with or without the G, will work.

Example,

Maximum tap pitch diameter for H limit

1/4-20 UNC GH5

= Basic PD + GH5 amount

= 0.2175 + (5 x 0.0005)

= 0.2175 + 0.0025

= 0.2200

Minimum tap pitch diameter for L limit

1/4-20 UNC GL3

= Basic PD – GL3 amount

= 0.2175 – (3 x 0.0005)

= 0.2175 – 0.0015

= 0.2160

D or DU Limits (metric taps)

D and DU limits are used for metric size ground thread taps. D represents a pitch diameter that is larger than the basic pitch diameter, and DU represents a pitch diameter that is smaller. The number after the D or DU, indicates the amount it is different than the basic pitch diameter. Each number after the D or DU is equal to 0.013mm, so an D3 or DU3 is equal to 0.013mm x 3 or 0.039mm. The D limit is the maximum pitch diameter of the tap, whereas an DU limit is the minimum pitch diameter. The minimum value for the D limit, and the maximum limit of an DU limit, are derived by applying the tolerances from the tap standards.

Example,

Maximum tap pitch diameter for D limit

M6 X 1 D5

= Basic PD + D5 amount

= 5.530mm + (5 x 0.013mm)

= 5.530mm + 0.065mm

= 5.595mm

Minimum tap pitch diameter for DU limit

M6 X 1 DU3

= Basic PD – DU3 amount

= 5.530mm – (3 x 0.013mm)

= 5.530mm – 0.039mm

= 5.491mm

Plus (oversize), Minus (undersize) Limits (whether inch or a metric)

When the specified amount, that the desired tap pitch diameter is to be over or under the basic pitch diameter, it is used to calculate the minimum limit, then the tolerance is applied plus to obtain the maximum limit.

If this maximum pitch diameter is an even multiple of, 0.0005 for inch sizes or 0.013mm for metric sizes, then the applicable G, GL D or DU can be determined. As an example, a 1/4-20 UNC +0.005 is not a GH10 (0.005/0.0005) , when adding the amount over size of 0.005 to the basic pitch diameter, it equals the minimum pitch diameter, then adding the tolerance, the maximum pitch diameter is now 0.0055 over the basic pitch diameter. 0.0055 / 0.0005 = GH11.

When the amount is not an even multiple of, 0.0005 for inch sizes or 0.013mm for metric sizes, it is used to calculate the minimum limit, and the maximum limit is established by adding a tolerance from the tap standard. In this case the tap is marked with “+” or “-“ followed by the amount, example 1/4 – 20 UNC + 0.0017, 1/4 – 20 UNC – 0.0017, M6 X 1 + 0.035 or M6 X 1 – 0.035.

G(S) Special Tap Pitch Diameter

When a tap does not fit H, L, D, DU, +, or – as described above and a maximum and minimum tap pitch diameter is provided, than the tap is marked with a G(S) followed by the maximum and minimum pitch diameter. Example, 1/4-20 UNC G(S) PD 0.2203-0.2198.

The information above as well as the tap pitch diameter tolerances, can be found in one of the two industry standards that govern the general dimension of taps in the United States.

ASME (American Society of Manufacturing Engineers), B94.9

USCTI (United States Cutting Tool Institute), Taps, Ground Thread

As you can see, determining the proper designation for the required tap limit can be quite confusing. The information is merely a way for you to determine what the pitch diameter limits are for a tap you may either have in your possession, called out on a print, etc. The selection of the proper tap pitch diameter is dependent on your application requirements. This blog did not discuss various application and how to determine the correct tap pitch diameter designation, we can cover that in a future blog. But until then, you can contact us with your application information, and we can work together to ensure your success.