Blog

Tapping Tip – How H-Limits Relate to Class of Fit (Part 2)

Welcome to another post on our Tapping Tips! This is the second part of a two-part series on the relationship of inch tap size and class of thread. In this second part, we will explain the relationship of tap sizes and class of threads. We should mention that H and L limits are also expressed as GH or GL, with the G meaning that tap has a ground thread. Either designation with or without the G, will work.

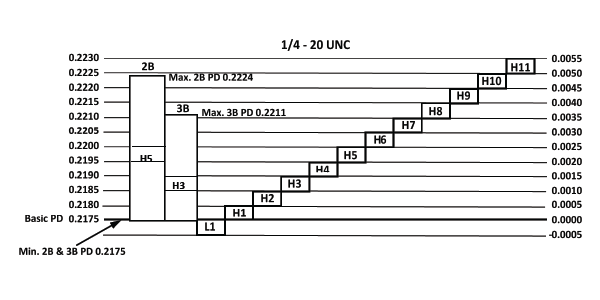

The figure below shows the 0.0005 incremental difference between H and L limits as well as their relationship to the basic pitch diameter.

Under normal tapping conditions a tap will cut larger than its measured size. Therefore, to avoid tapping oversize, you do not want to choose an H limit near the maximum pitch diameter for the class of fit being tapped. Conversely, if you want tool life, you do not want to use an H limit close to the minimum pitch diameter. The recommended H limits found in manufacturers’ catalogs and other industry literature, are based on it being at approximately 40% into the tolerance zone for the class of fit. In some cases it may be slightly more or less than the 40%. You can find our recommended H limit table in the technical section of our Special Taps, Dies and Gages Catalog.

The recommended H limit for a 1/4–20 UNC-2B is H5 and for class 3B is H3 as shown in the figure above.

When tapping conditions are not normal, the 40% may need to be adjusted. For example, if your machine is older, and the spindle runs out a little, you may want to consider a lower H limit than that recommended. Another example is, if the material being tapped is very ductal, and closes in after tapping, then you may want to use a higher H limit than that recommended. If the tapped hole is going to be plated after tapping, then you would want to use a higher H limit or even a tap pitch diameter that does not fall into an H limit at all, such that after plating it will fall within the specified class of fit.

Tap manufacturers cannot afford to stock every H limit for every size, so they only carry the recommended H limit for the standard class as well as a few others. But you may find, because you are tapping so many holes, that purchasing a special tap with a higher H limit can increase tap life and will pay for itself, resulting in a lower cost per tapped hole.

From the figure above, notice that the maximum of each H limit is the same as the minimum of the next higher H limit. In addition, the minimum of each H limit is the same as the maximum of the next lower H limit. This is due to the tolerance used in the manufacture of the tap. So, the tap pitch diameter size of a H3 could be the same as H4. By changing an H limit by only one increment will not solve an over or under size tapping problem. You will have to change by at least two H limits.

The above information for tap size and size designation (H) is what has been currently done in the United States. If a tap is manufactured outside the United States, it may be marked with the product thread class only and not an H tap size designation. That tap will be manufactured with a pitch diameter size of what the manufacturer thinks is best for the class of product thread being tapped. Foreign made taps, designed for tapping specific materials, may even take into consideration tap geometry. It may also consider the material being tapped and how that will affect final size of the tapped hole when establishing the tap pitch diameter size.

As you can see, the relationship between a tap limit and class of thread can be somewhat confusing. Please call us at 800.872.8277 or email Sales@GWSToolGroup.com with your application information, and we will send our experts to work!